Custom Design

Step 1

Your Idea

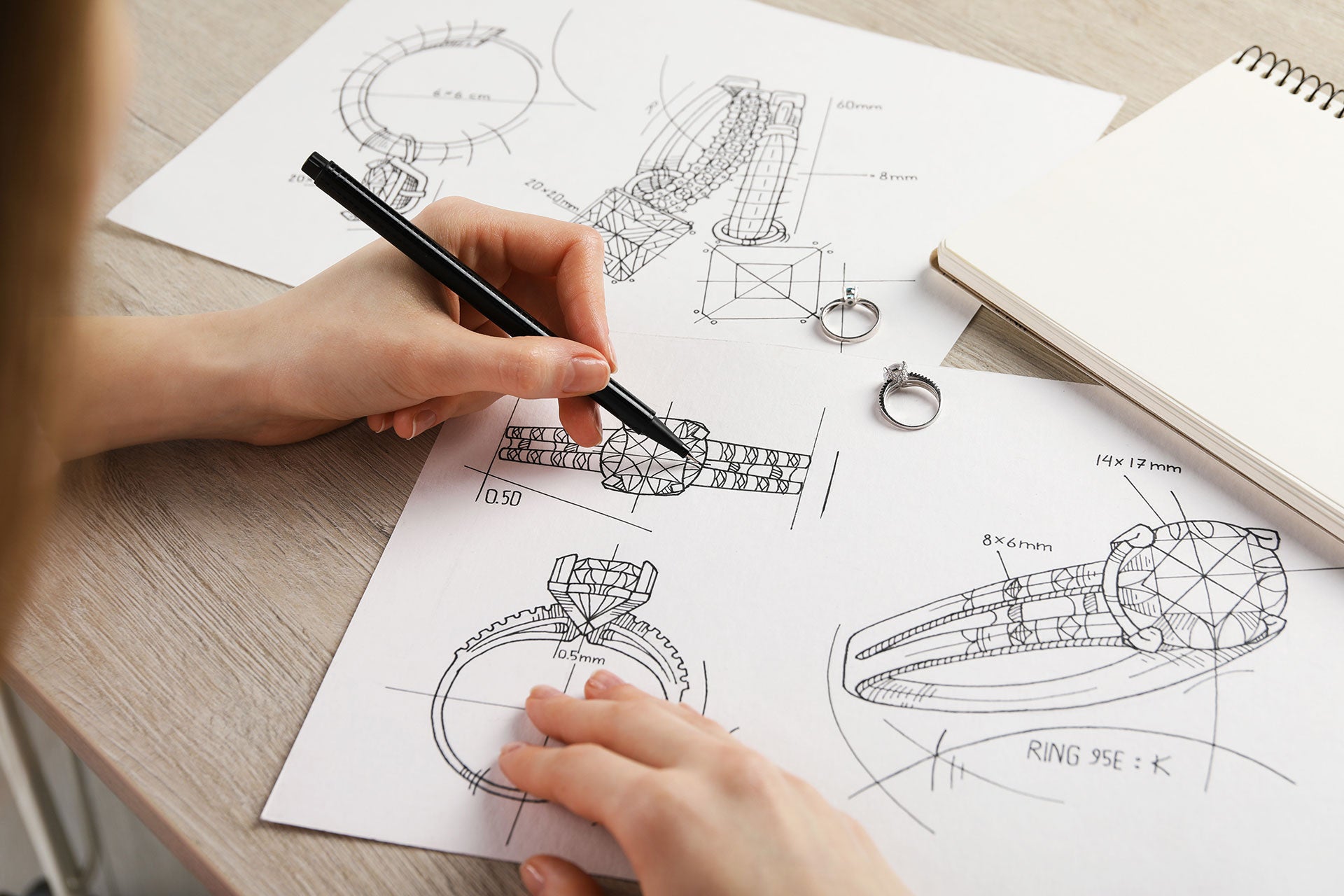

The creating and finishing of a piece of jewellery involves multiple complex and specific trades within the world of jewellery. The first and most crucial step to the design process! You have inspiration and passion to create a unique and special piece of jewellery. By collecting images and examples of elements you want to incorporate into your design, through an in-store discussion we can help you arrive at a final design concept for the piece of your dreams!

Step 2

Refining & Details

Once your design has been conceptually finalized, the particulars of the design can be finalized as well. Things like the colour and Karat of Gold, location and size of any precious stones in the ring, styles of settings for said stones, and of course the overall size of the piece. Selecting your Diamond(s) is often the most complex and difficult part of this phase, so we have created a small separate guide to help inform of the complex qualities of diamonds!

Step 3

Designing

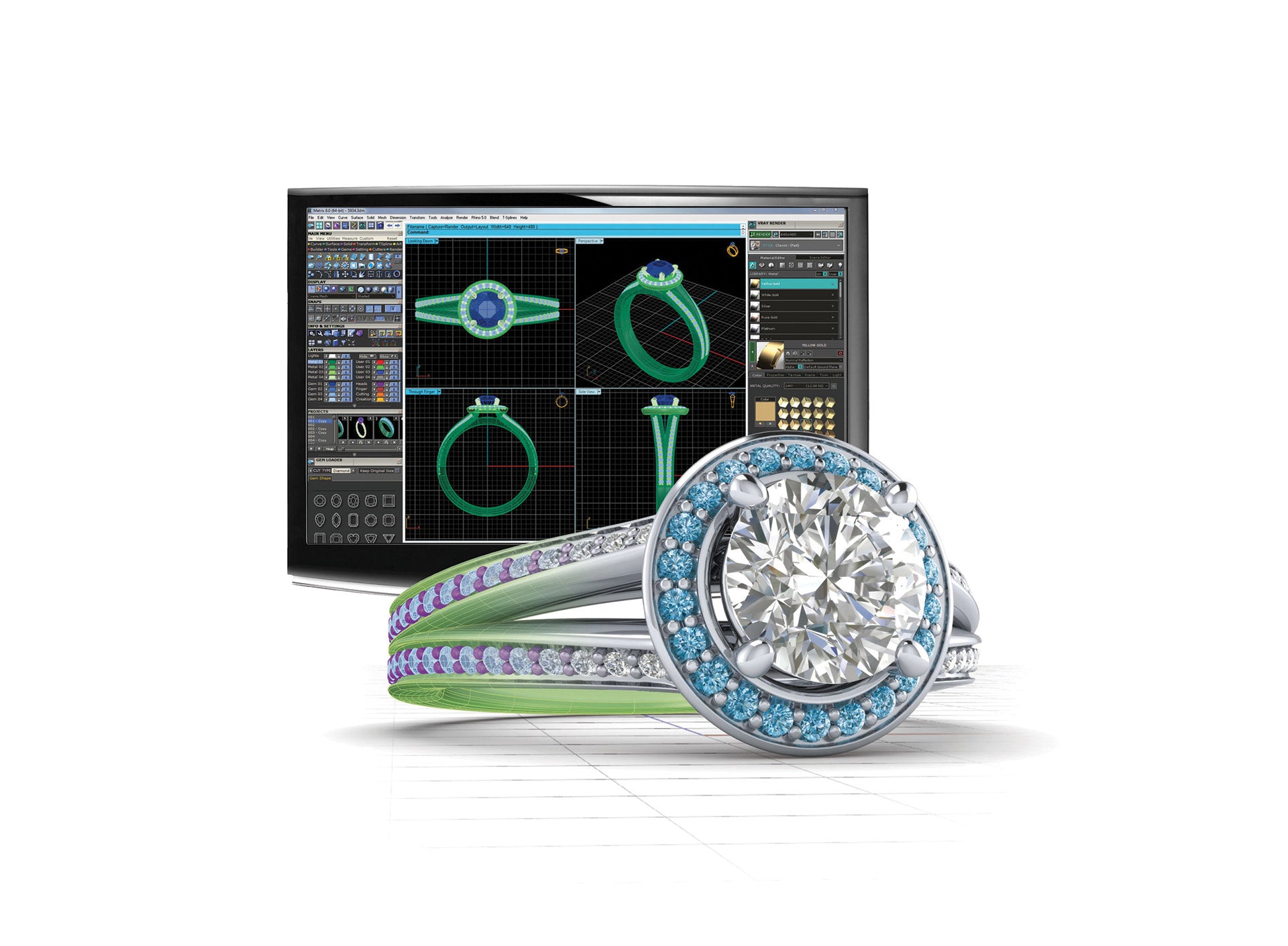

Now that we have your stones and general measurements of the size of the piece and its’ elements, we can begin to draw it in 3D in our Creative Design Program. Using this software, we can create a design that satisfies your artistic passion behind the creation of the piece, incorporating the elements you described in the first phase. Through in-store meetings we can facilitate a final product that will be both beautiful and true to the original design.

Step 4

Modeling

With the 3D drawing of the piece complete, we can cut a wax model of it using our in-house Milling technology. With this, you will be able to hold a version of your ring made of wax in your hand (without the precious gems) before you decide if the design is to your exact specifications. If anything about the design is not to your liking, we are always open to having a discussion about it so that we can find a way to make things right for you. We will also be able to inspect the design for any potential issues that may not be apparent until after the ring is cast. Fixing these oversights before casting is preferable in terms of both time and effort spent.

Step 5

Casting

Once we have perfected the design, created the wax model, and have your approval, the piece is ready to be cast. The wax model is taken to the metal caster, who will convert it into a metal model through the use of various metal casting techniques. Once the metal model is returned to us and is of a quality deemed satisfactory, we will move on to the final step of the custom process.

Step 6

Setting & Finishing

Now that the wax model of your design has been cast in your chosen metal(s), the raw metal product that we receive is then assembled and polished by our in-house goldsmith. Afterwards, if there are precious gems to be set in the piece, it is sent to the setter who uses very precise techniques and tools to cut away material from the setting to allow your stones to sit securely in the precise location determined in the design phase. Once the stones have been set, the piece is inspected and appraised in-store by our licensed professionals, and once deemed finished to their satisfaction, the piece is ready to be picked up by you!

Contact Us

Get Started Today!